Innovating Better Solutions

Safety Innovations Unique to MEC

Integrated Leak Containment System® (LCS)

Patent Number 11,112,060

LCS is a system of trays integrated to contain leaks and protect flooring while not interfering with safe machine operation.

- Integrated Design

- Safer Functionality

- Unrestricted Operation

- Optional on all MEC Slab Scissor Lifts

Xtra-Deck® (XD) Micro and Boom Models

Patent Number 12,252,380

Xtra-Deck® is there when you need it and folds up when you don’t. The additional 20 in. (51cm) working height allows for safe access through ceiling panels.

- Pull -Down Xtra-Deck® with associated telescopic guardrails

- Deploys or Stows in Seconds

- Standard on MEC Micro 13-XD and Micro19-XD Slab Scissor Lifts

Proactive Platform Safety System® (PPSS)

PPSS is a proactive solution that warns MEC operators of an overhead hazard to mitigate collision and entrapment.

- Ultrasonic Sensors

- Collision Mitigation

- Selector Switch for Warn & Stop or Warn Only

- Optional on MEC Booms and most Slab Scissor Lifts

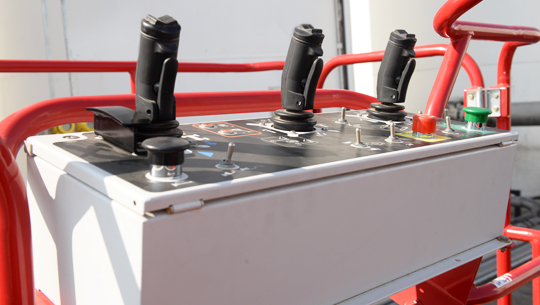

Lift Control Orientation

The control box on all MEC machines is angled away from the operator so potential entrapment situations are mitigated by a resulting downward movement.

- Angled Lift Control & No Foot Switch on Booms

- Comfort and Mobility

- Safety Time-Out

- Standard on all MEC Booms and Slab Scissor Lifts

Featured for Differentiation

Direct Electric Drive Scissor Lifts

MEC’s electric scissor lifts are powered by direct electric drive for high efficiency, better performance and higher product residual value.

- Significantly Longer Times Between Battery Charges for Extended Duty Cycles – Typically 2 to 3 times longer

- DC Drive Motors for Smoother, More Precise Controls

- Quiet Operation for Confined Areas

- No Hydraulic Leak Points on Drive

- Standard on All Electric Slab and Midsize RT Scissor Lifts

Integrated Sheet Material Tray

MEC’s integrated sheet material tray is designed for greater productivity, reduced fatigue and increased safety while meeting or exceeding the requirements of applicable standards.

- Manufacturer Approved vs. Jobsite Addition

- Stability Requirement Confirmed

- Standard on select Slab and RT Scissor Lifts

MEC’s Signature “Big Black Wheel” – Jib Terrain Guide

MEC protects the jib and platform from damage by including a nylon roller wheel at the end of the jib. This roller wheel relieves forces that would otherwise cause damage. Standard on all MEC Telescopic Booms.

MEC’s No Footswitch for Safer Boom Operation

MEC Booms are controlled without the use of a footswitch for better maneuverability, greater range of motion and safer operation.

- 3 joystick controllers, each with an enable switch

- Better ergonomics from no footswitch allows the Operator a posture that enables better visibility, sturdier stance and fewer distractions

- Reduced entrapment risk

- Standard on all MEC Booms

MEC’s 2-Section Boom Operation

Sometimes less is more and MEC’s 2-section boom exemplifies that compared to 3-section booms.

- More abuse tolerant

- Lower maintenance than a 3-section boom as it avoids:

- Wire rope or chains in the pulley system and the need for inspection and periodic re-tensioning

- The complexity of parts associated with sheaves and boom safety locking mechanisms

- The limit switches often integrated to detect a slack rope or chain

- Half as many wear pads as a 3-section boom

- Standard on all MEC Booms